Sustentability

HomeSustentability

Sustainable Production

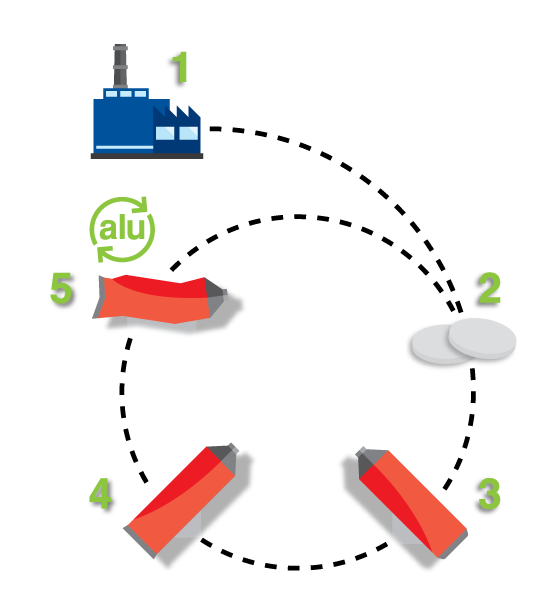

1. Aluminum Production

Aluminum is produced from one of the largest natural resources on Earth: bauxite. Aluminum is transformed into slugs after a roller coating process.

2. Slug Production

The slug obtained has a 99.7 % purity: its qualities and properties are optimal.

3. Tube Manufacturing

The tube takes its final shape after the extrusion of the slug: whether sealed or not, fixed length. The step from the oven to the printer (printing in dry offset) is performed by optimizing the resources used and by using water based coatings (varnish, lacquer), thus reducing the use of solvents.

4. Product Consumption

Aluminum tube packaging is omnipresent in the universe of the final consumer: in the kitchen, in the bathroom or in the drawer of a pharmacy. Advantages of the container: a perfect dosage, longer product life, use of the entire product without waste and, above all, an easy container to recycle if you have a simple "citizen gesture": to facilitate the collection of used tube , the consumer must separate the cap from the tube and deposit it in the corresponding containers

5. Recycling

The containers in aluminum tubes can be found everywhere in the end consumer universe: in the kitchen, in the bathroom, or in pharmacy shelves.

The advantages of the container are: perfect dosage, longer shelf life of the product, use of the whole product without waste and, above all, an easy-to-recycle container, if there is a simple “citizen gesture”: the consumer must separate the cap of the tube and put it in the corresponding containers in order to facilitate the collection of the used tube.